Centralized Coolant Filtration Systems

Roll Coolant Systems, Roll Coolant System, Manufacturer, Supplier, Exporter, Pune, India

Roll Coolant Systems

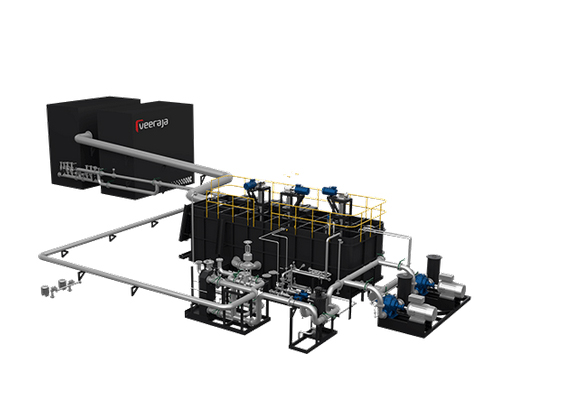

Roll Coolant Systems For Cold rolling mill :

Cold rolling mills filtration system has many functions. It has to remove the scale and scum generated during rolling. The temperature has to be controlled along with flow and pressure.

A cold rolling mill system usually consists of a large tank. The dirty fluid enters into the dirty fluid compartment. Using baffles the complete flow is passed through Magnetic separator into the semi clean compartment. This fluid is then sucked by large pumps and passed through self-cleaning filter and PHE skid to control the temperature. A pressure control valve ensures constant pressure is supplied to the mill.

The tanks have agitators to continuously mix the coolant. Belt skimmers are also mounted on the tank to remove the floating scum. To maintain the temperature of the tank, either electrical heaters are placed in thermic fluid tubes or the coolant is passed through housing heated by electrical heaters or steam. If finer filtration required then a different set of pumps are used to transfer dirty fluid to pneumatic vacuum filters.

Roll Coolant Systems For Galvanising line :

Galvanising line filtration system has many functions. It has to remove the scale and scum generated during rolling. The temperature has to be controlled along with flow and pressure.

A Galvanising line system usually consists of a large tank. The dirty fluid enters into the dirty fluid compartment. Using baffles the complete flow is passed through Magnetic separator into the semi clean compartment. This fluid is then sucked by large pumps and passed through self-cleaning filter and PHE skid to control the temperature. A pressure control valve ensures constant pressure is supplied to the mill.

The tanks have agitators to continuously mix the coolant. Belt skimmers are also mounted on the tank to remove the floating scum. To maintain the temperature of the tank, either electrical heaters are placed in thermic fluid tubes or the coolant is passed through housing heated by electrical heaters or steam. If finer filtration required then a different set of pumps are used to transfer dirty fluid to pneumatic vacuum filters.

Roll Coolant Systems For Pickling line :

A pickling line requires a tank to prepare the solution. Because of the fluid properties this tank is generally of stainless Steel material. For the proper functioning of the line, the fluid has to be prepared with a proper concentration. Mixing of the powder with the fluid has to be proper. A screw conveyor is used to drop specific quantity of powder in the tank. It has a hopper to store the powder.

An agitator is used to mix the powder properly. A pumping station pumps the fluid back to the process.

Features & Benefits

• Complete in house design and manufacturing of all products required in the system• Tank :

• Rounded corners to avoid accumulation and rusting in corners.

• With manholes, inspection hatch, railing and ladders

• Magnetic Separators :

• Vertical or horizontal candle

• Simple and rugged design for 24x7 operation

• Self-cleaning filter :

• Modular design

• Economical design replacing the costly stainless steel wedge wire screens

• PHE and pressure control skid :

• Plate type heat exchanger with automatic temperature control valve.

• Automatic pressure control valve with complete flow back pass arrangement during & rolling direction changeover

• Agitator and Skimmer :

• Rugged design for 24x7 operation.

• Option of Individual frame with bottom bearing/bush for added stability

• Special blade design for proper mixing

• Heating options :

• Electrical heaters in tubes with thermic fluid placed inside tanks.

• Steam heating jackets inside tanks

• Forced circulation PHE with steam and PRV

• Forced circulation through heater placed in separate housings.

• Fine filtration :

• Separate pumping station

• Pneumatic Vacuum filter

• New century design eliminates the blower

Roll Coolant Systems For Cold rolling mill

Roll Coolant Systems For Galvanising line

Roll Coolant Systems For Pickling line